Canadian Timberframes purchases Canada’s largest Hundegger CNC machine with

6-axis robot

BC based timber frame manufacturer increases mass timber capabilities with the installation of new CNC machine, and facility expansion.

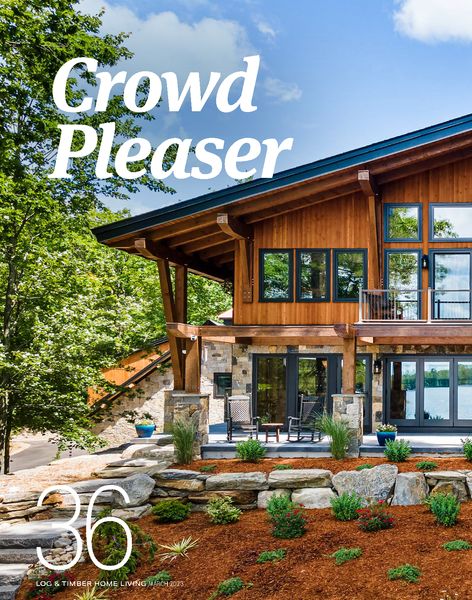

GOLDEN, BC — Canadian Timberframes (CTF), a premier design, manufacturer in the timber frame industry, announces that it has purchased Canada’s most equipped Hundegger K2 Industry 1300 machine. The largest and most advanced K2 Industry to come to Canada, this machine will increase CTF’s timber size capacity by 500 per cent; enabling them to cut large scale engineered wood products. This machine is scheduled for installation in Fall 2022.

“This expansion and new machine is our commitment to our expanding industry and our industry partners. Combining both the most advanced K2 Industry 1300 with an in-sequence 6-axis robot, this new machine allows us to meet the growing requirements of the mass timber industry, while simultaneously increasing our capacity to produce authentic timber frame products,” says Jeff Bowes, President and Owner of CTF. This announcement is accompanied by the news that CTF is increasing the size of their facility by 50 per cent, adding an additional 10,000 sq. ft. to their facility, to accommodate this machine and further optimize production.

The purchased CNC machine with a 6-axis robot is one of the most efficient and comprehensive solid wood processing machines for heavy timber and glulam in the mass timber industry. With over 34,000 sq ft of manufacturing capacity to come, this new machine enables them to run larger timber sections (18 x 51 x 70’), handle more complex & larger scale commercial projects in both timber & mass timber, and deliver results that align with CTF’s reputation of excellence.

Timber and engineered wood products are a strong, low-carbon

building alternative to concrete and steel.

22 years after Canadian Timberframes brought Canada’s first Hundegger K2 machine to the country, they are once again innovating. “We congratulate Canadian Timberframes on the upcoming installation of the largest and most advanced K2i in Canada, and one of the largest & most advanced installations in North America,” says Hans Hundegger, founder and president of Hundegger.

“We are preparing for the future of this organization; our success has been built on quality products and services. This investment back into the company is not only for our clients but our employees. This investment allows CTF to remain competitive, strengthening our market position and offering world class Timber Frame products, while growing within the mass timber and tall wood construction industry” says Stephanie Bowes, Vice President of CTF.

“Canadian Timberframes promises extraordinary quality and professional service; it is our highest priority, focus and my promise!” says Jeff. “As far as our customer service is concerned, construction will not affect our regular operations”

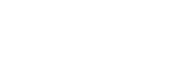

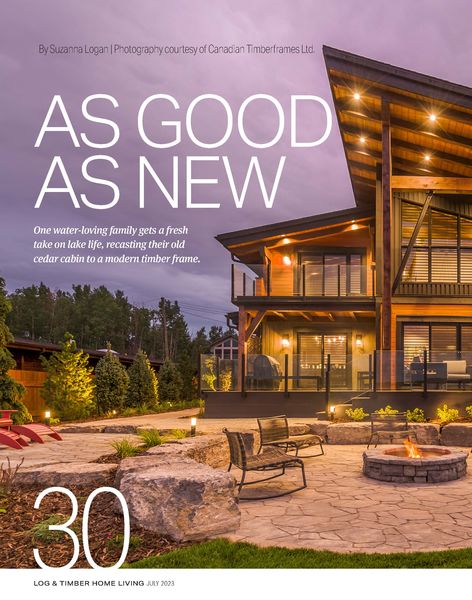

Canadian Timberframes works closely with Clients, Architects & Builders throughout North America – Servicing the entire United States; and beyond.

To contact us about your project visit www.canadiantimberframes.com/contactus or download our ebook, visit www.canadiantimberframes.com/ebook; to subscribe to our monthly newsletter please visit https://www.canadiantimberframes.com/newsletter

About Canadian Timberframes: CTF is the leading North American manufacturer and provider of heavy timber frame solutions. We manufacturer everything you need to take your home to lock up. We offer only the finest products and exceptional service. For more information please visit www.canadiantimberframes.com.

#Expansion #Wood #Timber #TimberIndustry #TimberFrame #LowCarbonAlternative #Hundegger #MassTimber #TallWoodConstruction #EngineeredWood #Glulam